Pump installations in soils subject to groundwater requires some care and understanding of the forces at play. An installation in summer time when ground water is low, can become an entirely different issue in spring time. As water tables rise, the forces against the chamber can cause shifting and damage the connections or the chamber. The image below demonstrates the power of buoyancy against improperly ballasted concrete tanks.

Installing lightweight pump chambers in these conditions must follow the original equipment manufacturer’s instructions and the design engineer’s specifications.

We have seen a number of ‘creative’ methods that have tried and failed in the installation of these systems.

This field poured ballast ring is a very risky proposition. The lifting hook is doomed to fail and will cause damage to the equipment and possibly hurt the workers trying to hoist this into position.

“Wet Activating” concrete mix might work around shallow fence posts; but pump chambers will not be secured properly. This guy might as well throw his wallet in the hole for all the benefit he is seeing.

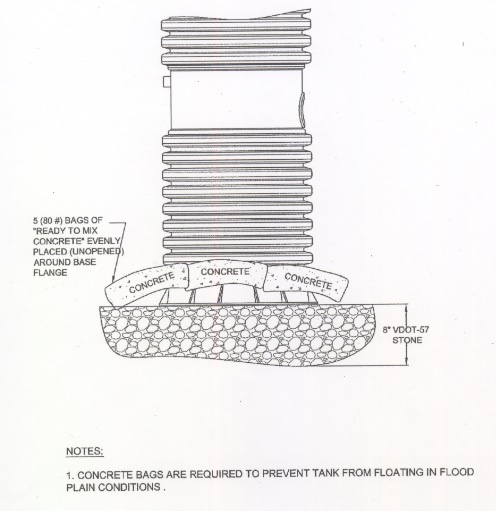

We believe the engineer will say this was a graphic depiction showing concrete is required. An upgrade from pouring bags of concrete in the hole. but still a poor application.

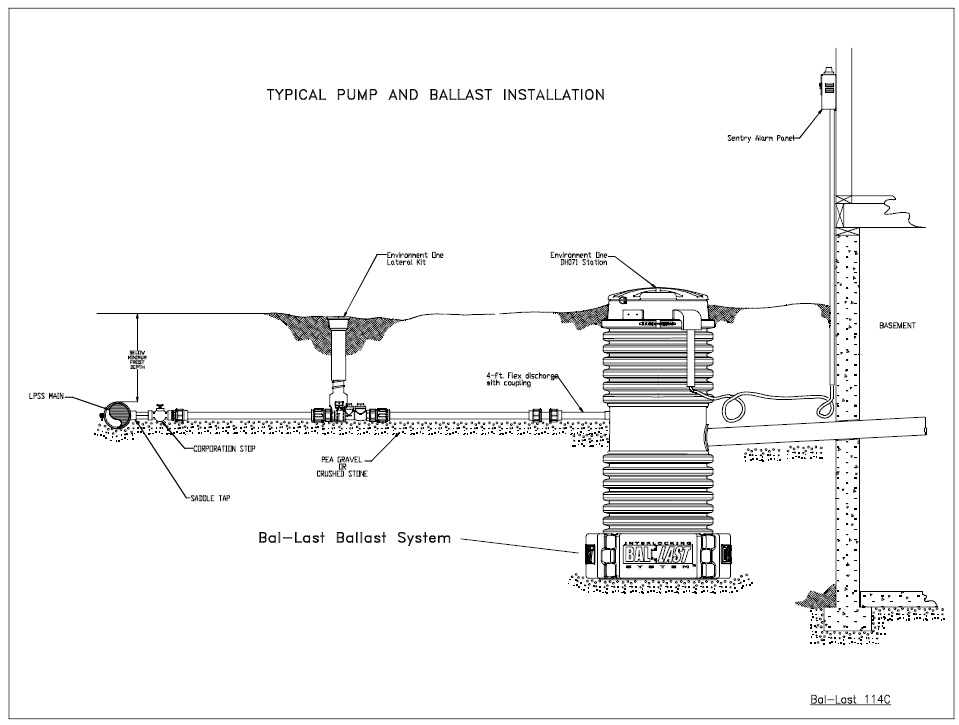

Now this is much better. The structural Bal-Last ring conforms to the tank ribs and provides an immediate structural ring permitting immediate inspection and backfilling. Doing it right adds time saving, safety and reliability.