June 2015

The community of Port Clinton Borough and Port Clinton is located a few miles northwest of Hamburg, Pennsylvania. Located off Route 78 you will pass through the commercial and retail development around the newest Cabela store. Just 2 miles to the north on Route 61 you will venture back in time to a very rural and peaceful setting. Port Clinton borders the Schuylkill River and the John Bartram Trail.

Mayor Jeff Schappell was kind enough to meet with us and described the efforts to provide sewer service to his community. Soil conditions in the region and the hilly terrain made for challenges with on lot installations. Ledge and rocky soils are in ample supply in this area.

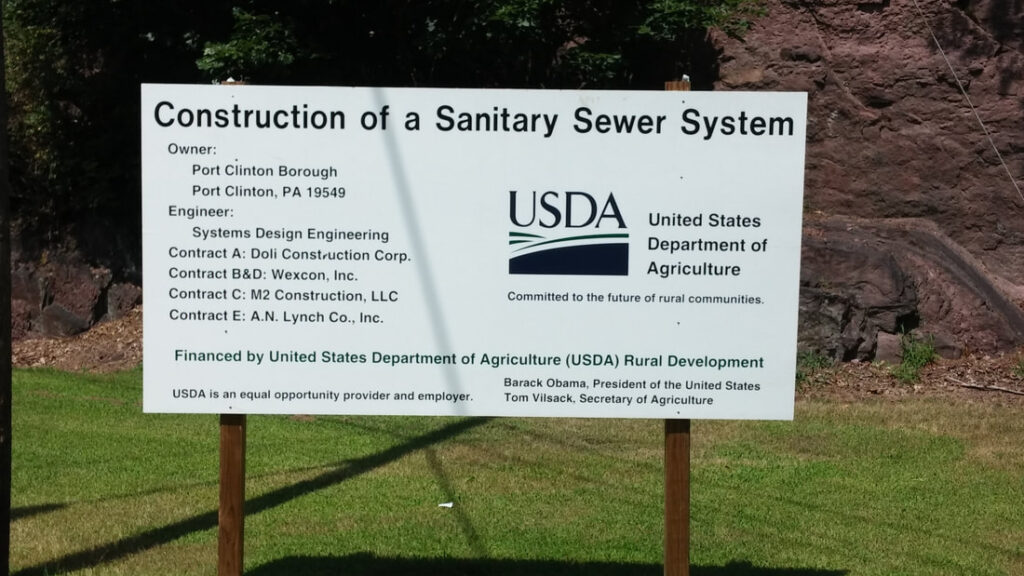

Port Clinton was passed over for public sewers many years ago and has recently completed a pressure sewer project under USDA funding support.

The recent project brought pressure sewer service to 25% of the community. Wastewater is pumped 2 miles to the city of Hamburg for treatment.

Our local Distributor, Site Specific Design (www.sitespecificsales.com),worked with the Designers from System Design Engineering and the project contractors. Bal-Last was chosen to provide pump installation solutions in very challenging locations.

Mayor Schappell was very impressed with the Bal-Last System. Jeff reported that at his home connection installers were able to install the pump and backfill in a very small area. That night they had a very heavy rainstorm that caused puddling around the fresh backfill. “Nothing moved” and his pump system was not impacted by the sudden accumulation of surface and ground water.

The Bal-Last system has been a great advantage to many of the homes with very small lots and limited access according to Jeff. The local installers seem pleased with the system that takes little time to assemble. The Bal-Last System was critical to the design engineer because over half of the pump stations are in the floodplain.

Bal-Last delivered 48 sets of ballast rings on pallets of 24 blocks or six full sets per pallet. Installers then could stage pumps on the original shipping pallet and install the Bal-Last just prior to placement.

Bal-Last installation can be made at a staging area or on level ground prior to placement of the pump.

The lifting hooks provided with each block allow for easy maneuvering of the pump and ballast.

During our visit we witnessed a very challenging installation

The Bal-Last ring can be seen slightly exposed in the base backfill. Final discharge piping is with a 1-1/4-inch SDR 11 HDPE pipe whip. Each inlet line is provided with pipe trap and exterior vent to meet Pennsylvania Code.

This installation shows how tight the lots are and the challenges of mixing and pouring concrete ballast. The pump installation behind this retaining wall (below) leaves little room to work. Fortunately, the contractor was able to place the pump and Bal-Last as one assembly.

The image above shows the excavated area behind the retaining wall where the pump was placed.

Start Up Inspections

Pumps are inspected following installation by Site Specific Design personnel. One key advantage was a greatly reduced inspection service by the consultant engineer. “Knowing the pumps all had Bal-Last allowed the engineer to spend less time overseeing the installation.”

Find out more:

www.sitespecificsales.com